Marion Process Solutions

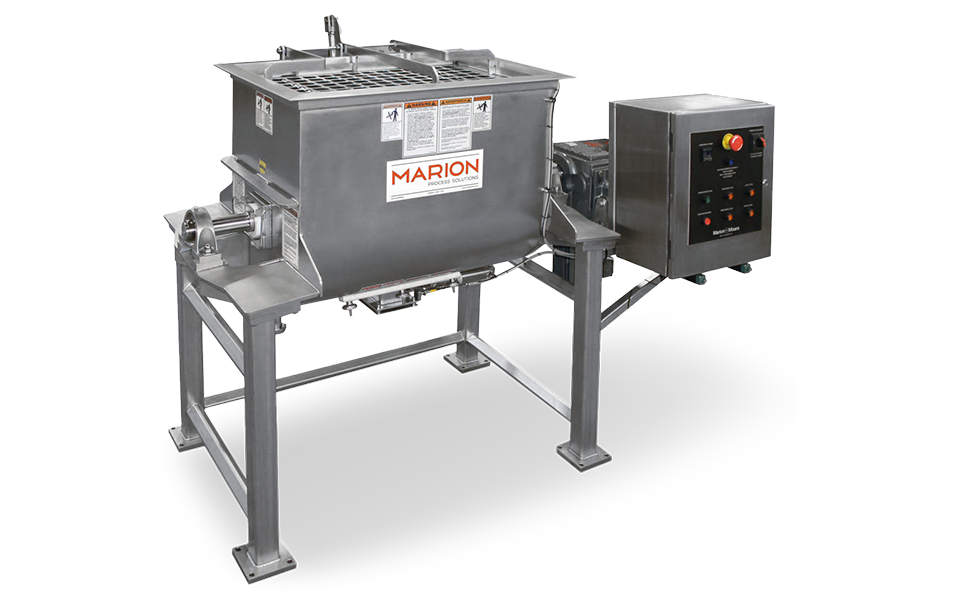

Horizontal Batch Mixers

DESIGNED TO KEEP YOUR PROCESS MOVING

The name Marion is synonymous with horizontal batch mixing. For over 80 years, we have set the standard by which all other mixers are measured. From our flexible and ready-to-work Heartland Ox, to a fully custom design based on your processing needs, Marion has the solution you need. Your industrial batch mixer will be the cornerstone of your process solution for decades to come, so choose wisely, and choose Marion.

Continuous Process Batch Control Mixing gives the speed advantages of continuous mixing, with the quality mixing of batch

Sanitary, food and pharmaceutical grade construction and materials available

Optional automated Clean-in-Place (CIP) systems for fast and efficient cleaning

Multiple custom size, input, output, paddle and other features available

Lab and mix testing services available

Design, integration and aftermarket support

Typical Horizontal Batch Mixer Configurations

Marion has over 85 years of experience in mixing solutions. Here are a few examples of solutions we've made before; what will we make for you?

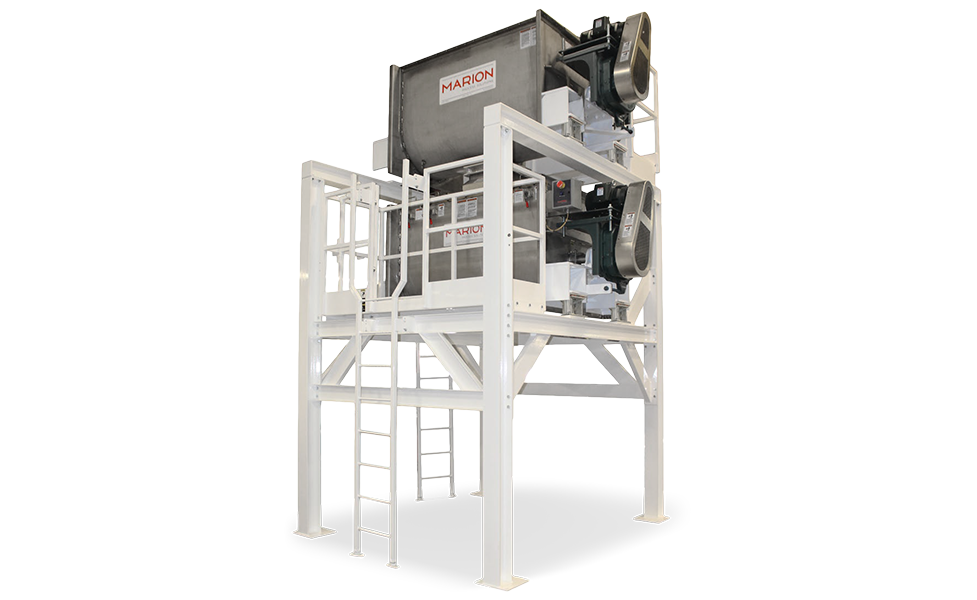

Small-to-Medium Horizontal Batch Mixer Configuration Industries: Plastics, Minerals, Chemicals

View Configuration Details

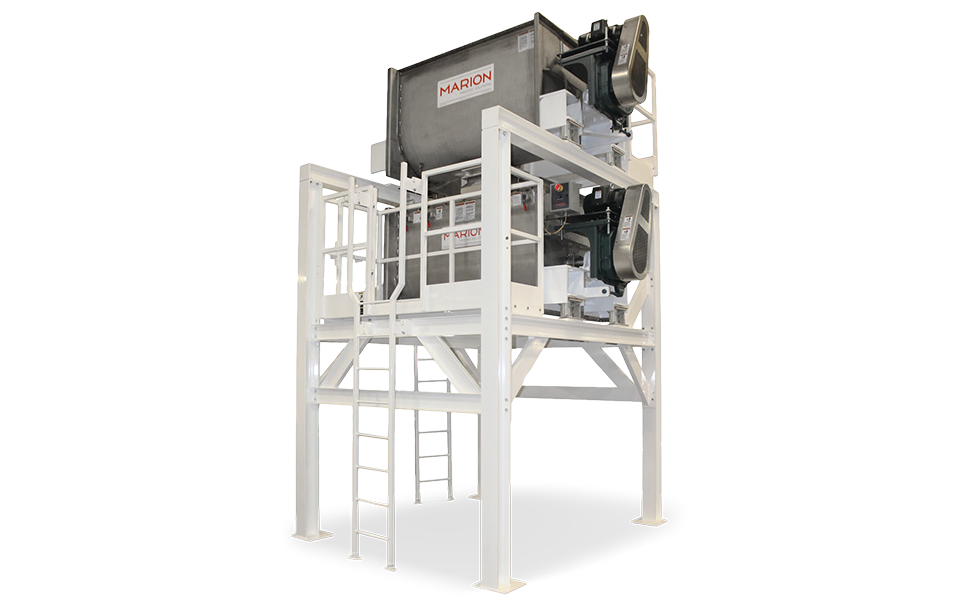

Mineral, Pharmaceutical & Nutraceutical Mixing Configurations Industries: Minerals, Pharmaceutical / Nutraceutical

View Configuration Details

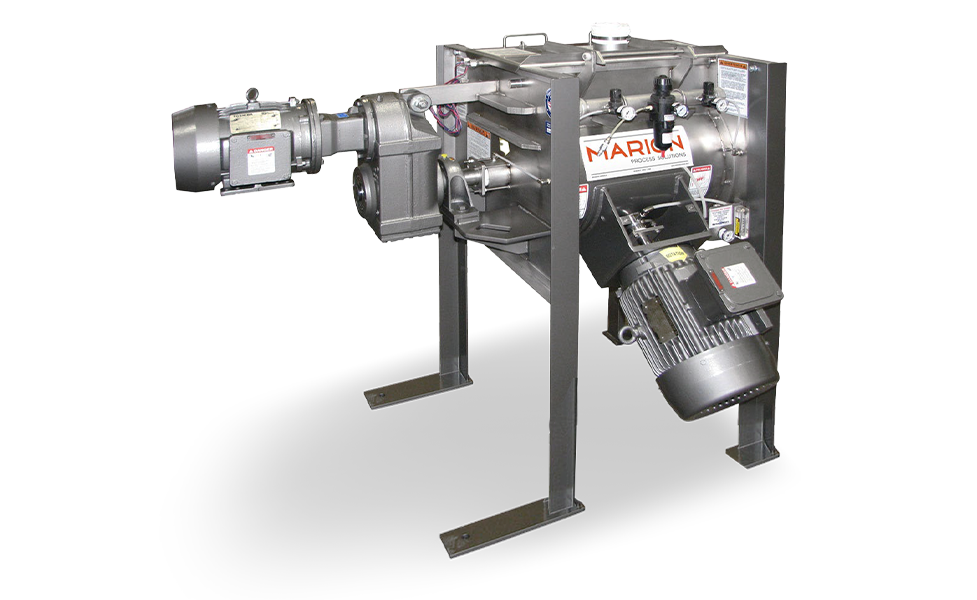

Animal Nutrient & Feed Processing Equipment Configuration Industry: Minerals

View Configuration Details

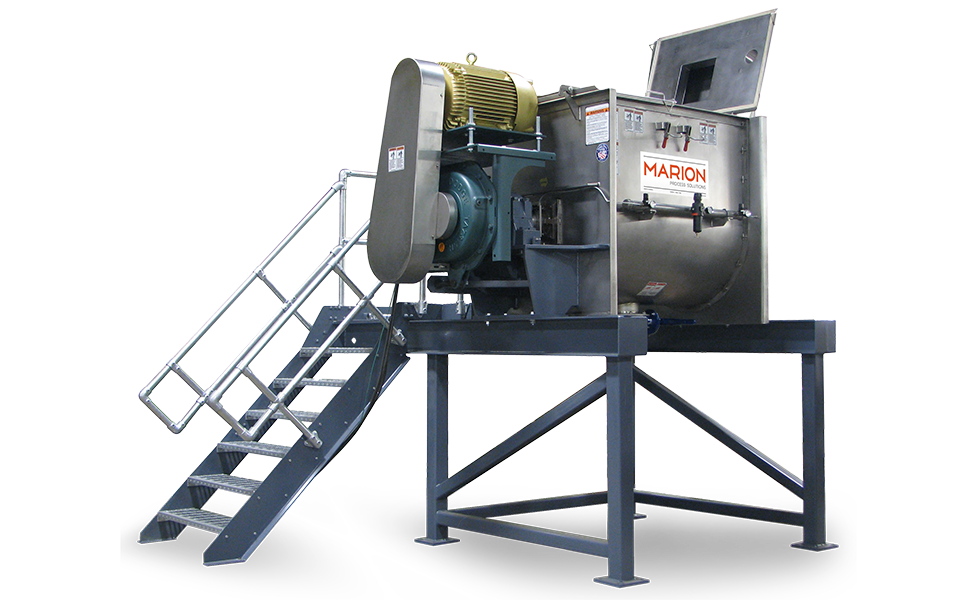

Bakery Ingredient Mixer Configuration Industry: Food & Beverage

View Configuration Details

Flavor Dosing System Configurations Industries: Food & Beverage, Coffee

View Configuration Details

Flour Blending Equipment Configuration Industry: Food & Beverage

View Configuration Details

Grout Powder Processing Equipment Configuration Industry: Minerals

View Configuration Details

Nutraceutical Powder Blending Equipment Configuration Industry: Pharmaceutical / Nutraceutical

View Configuration Details

Food Crumbling Mixer Configuration and Custom Options Industry: Food & Beverage

View Configuration Details

Animal Nutrient Ingredient Equipment Configuration Industry: Minerals

View Configuration Details

Sulphate Slurry/Polyol Liquid Equipment Configuration Industry: Chemicals

View Configuration Details

Powder, Seasoning & Dehydrated Vegetable Equipment Configuration Industry: Food & Beverage

Marion's decades of expertise in mixing and food processing combined with the following custom options made this batch mixer configuration for food and soup processing possible.

View Configuration Details

Iron Powders & Resin Processing Configuration Industries: Plastics, Chemicals

View Configuration Details

Plastic Pellet Processing Equipment Configuration Industries: Plastics, Chemicals

View Configuration Details

Plastic Powder & Pellet Mixer | Configuration Industries: Plastics, Chemicals

View Configuration Details

Food Grade Resin PVC Processing Configuration Industries: Plastics, Chemicals

View Configuration Details

Nutraceutical Powder Mixing Equipment Configurations Industry: Pharmaceutical / Nutraceutical

View Configuration Details

Pharmaceutical Powder Mixing Equipment Configuration Industry: Pharmaceutical / Nutraceutical

View Configuration Details

Bentonite, Minors & Water Processing Configuration Industries: Minerals, Chemicals

View Configuration Details

Aluminum Powder & Boron Processing Equipment | Configuration Industries: Minerals, Chemicals

View Configuration Details

Borax & Oxide Powder Mixing Equipment Configuration Industries: Minerals, Chemicals

View Configuration Details

Bakery Premix Manufacturing Equipment Configuration Industry: Food & Beverage

View Configuration Details

Chili Powder Processing Mixer Configuration Industry: Food & Beverage

View Configuration Details

Ricotta Cheese Batch Mixer Configuration Industry: Food & Beverage

View Configuration Details

Gelatin Powder Processing Equipment Configuration Industry: Food & Beverage

View Configuration Details

Deli Salad Mixers | Custom Options Industry: Food & Beverage

View Configuration Details

Coffee Processing Equipment | Custom Options Industries: Coffee, Food & Beverage

View Configuration DetailsChoosing the Right Industrial Mixer Handbook

Ensure your next mixer is fine-tuned to your processing needs. Learn the right questions to ask and the fundamentals of mixer design in our convenient handbook..

Get the Handbook!More from the Experts at Marion

Explore Resource LibraryMarion in the Mix Blog Stay on top of critical developments in material processing technology, industry trends, equipment application tips and more with Marion in the Mix today!

- Marion Process Solutions and Partners Celebrate the Opening of a New UK Facilityon October 23, 2024

Our new facility in Darwen, UK, was officially opened by the Mayor of Blackburn with Darwen, Councillor Brian Taylor, on 15th October. Over 100 guests attended the event, which featured guided tours of the 60,000 sq ft facility and live demonstrations of AHS-AMP’s equipment.

- 3 Ways Our New Chopper Design Gives Processors an Edgeon October 8, 2024

Choppers are an effective tool for breaking down clumps or dense materials in your mix, significantly enhancing the efficiency of your mixer or blender.

- 4 Reasons to Switch from Manual to Automated Cleaningon September 12, 2024

Establishing an efficient and reliable cleaning process is a challenging yet crucial task for material processors.